Market Report 2026: Critical Perspectives on Supply and Purchasing Strategy

At Matrix Electrónica, as strategic partners in our clients’ value chain, we constantly monitor the variables that impact the availability and cost of technology. Following a detailed analysis of manufacturing capacities and the trends of the leading companies in the sector, we present our updated vision on the challenges that will define the remainder of the year and the coming years.

1. Memory Sector: A Structural Challenge (DRAM and SSD)

Massive demand driven by Artificial Intelligence has caused an unprecedented shift in production capacity toward high-performance memory (HBM), cannibalizing the manufacturing of standard solutions.

- Time Horizon: The most conservative projections in the sector indicate that supply tension and price volatility will not normalize until 2028.

- Impact on Operations: Lead times for industrial DRAM and SSD remain in the 20-36 week range. This structural shortage exerts continuous upward pressure on costs in euros, making early financial and procurement planning indispensable.

2. Transition in Processors: The “Bottleneck” of the 10nm

The strategy of leading manufacturers, with Intel at the forefront, currently prioritizes migration toward cutting-edge architectures, directly affecting mature nodes.

- 10nm Situation: These nodes, fundamental to the current industrial ecosystem, are suffering a drastic reduction in manufacturing share, limiting the available supply for new projects.

- Turning Point: We do not foresee a tangible improvement in supply until the first quarter of 2027 (Q1 2027). It is estimated that, by that date, the adoption of platforms based on 1.8nm architectures will be broad enough to release the pressure on 10nm production lines.

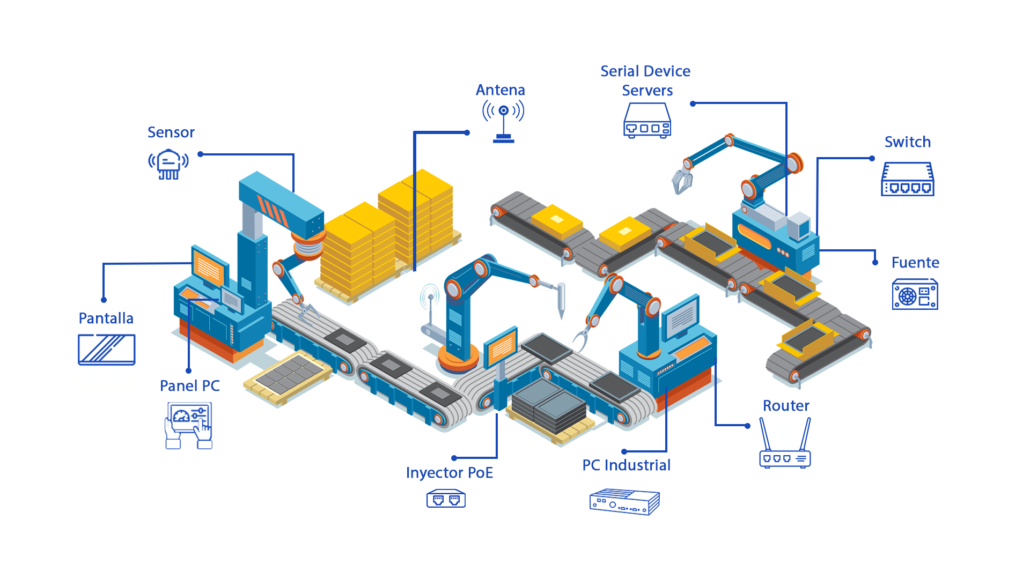

3. Transversal Tensions in the Component Ecosystem

In addition to advanced semiconductors, at Matrix Electrónica we observe a ripple effect in component families essential to any electronic design:

- Microcontrollers and Power: MCUs (8/16-bit and ARM Cortex) and power devices (MOSFET, IGBT, SiC) maintain critical lead times ranging between 18 and 60 weeks.

- Passive and Discrete Components: We detect additional delays in standard packages and critical passives, affected by instability in logistics routes and the rising cost of raw materials.

Risk Analysis and External Factors

Three critical variables are amplifying the complexity of the current market:

- Prioritization of Cutting-Edge Nodes: Global investment is shifting from mature nodes (≥40nm) toward latest-generation nodes, leaving the traditional industrial component base underserved.

- Geopolitics and Logistics: Trade frictions and new export controls slow down material flows, increasing operating and transportation costs.

- Stocks at the Limit: Following the inventory adjustment of the last two years, safety levels in global distribution are at historic lows, eliminating any reaction margin to unexpected spikes in demand.

Recommended Roadmap by Matrix Electrónica

To protect your operational continuity and ensure the competitiveness of your costs in euros, we strongly recommend:

- Formalizing forecasts for 2026 and 2027 immediately.

- Closing long-term supply agreements to lock in production quotas before the end of the next quarter.

- Evaluating preventive redesigns toward new-generation platforms (1.8nm) whenever your product’s lifecycle allows.

The entire Matrix Electrónica team is at your full disposal to conduct a joint working session, analyze your forecasts, and design a supply strategy that guarantees your production stability.